Choose Logistics Services to Optimize Your Supply Chain

Whether you’re a manufacturer, supplier, or buyer, a reliable supply chain is critical to your business success. In an increasingly competitive market, ensuring customers receive goods on time and in perfect condition is non-negotiable.

A high degree of customer satisfaction is rapidly becoming the golden standard of supply chain success. Approximately 83% of businesses recognize just how essential the supply chain is in enhancing the customer experience and are aligning their goals to prioritize 3PLs as a key partner in their business success.

So, how do businesses set themselves up for success with so much customer satisfaction at risk via the businesses’ supply chain? While sourcing a reliable transportation and warehousing provider is the first step, it is only through working through the details of the requirements that you can ensure their logistics services will adequately meet your needs.

Innovative shipping solutions, warehousing, and plant support services are integral to a successful supply chain. Here’s how each of these services can save your business time and money and ensure your products arrive as ordered every time.

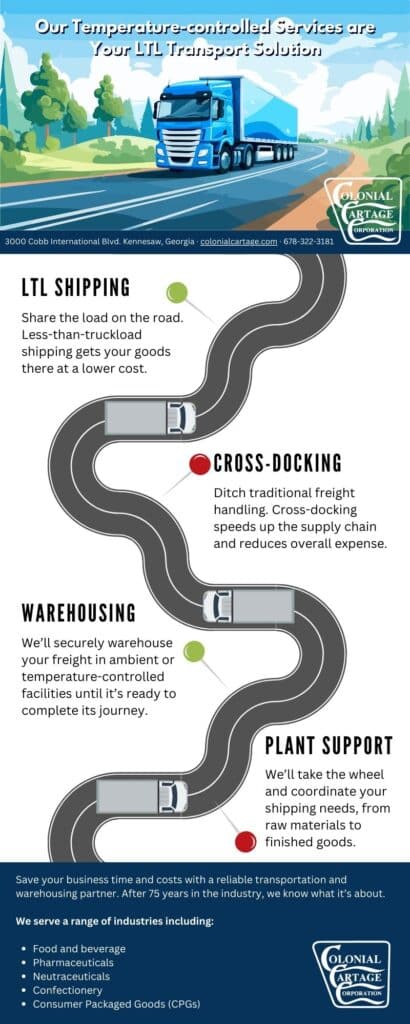

Temperature-Controlled LTL Shipping

Less-than-truckload (LTL) freight consolidation allows clients to ship smaller orders to their destinations without paying the full cost of full truckload shipping. This cost-effective solution consolidates orders from several customers for the same destination.

Freight consolidation works just as well for temperature-controlled carriers transporting LTL orders as it does for ambient programs. There is little operational difference except for maintaining the cold chain custody from dock to dock.

LTL freight consolidation reduces overall costs, pro-rating the cost of transport with other shippers to the same destination, and provides a platform for getting your orders to their destinations more quickly and with less handling.

Cross-Docking

Cross-docking is the process of transferring products from one trailer, container, or rail car across a staging area to another in a short space of time. This service is appropriate if your products need to change the mode of transport or use similar equipment with a different carrier in order to get to the next or final destination. Cross-docking reduces inventory holding times and warehousing costs if executed properly.

Traditional warehousing requires the multiple handling of your goods as they’re unloaded, received, put away, then flipped to be picked, staged, and loaded. Cross-docking simplifies this process to unloading, receiving, staging, and loading, in turn reducing warehouse dwell time and additional handlings.

Facilities that offer cross-docking services streamline your supply chain, avoiding unnecessary storage dwell time. The process can expedite your orders to get your products to your customers faster than conventional warehousing means.

Warehousing

Not all products, particularly food products, can be stored in the same temperature environment or in proximity to other products that might contain allergens, so choosing the correct warehouse facility for your products is essential. Ambient and temperature-controlled warehousing protects both ambient and temperature-sensitive food-grade products like confectionery, snacks, food packaging, dry grocery, pharmaceuticals, beverages, and consumer packaged goods (CPGs).

The carrier’s Transportation Management System (TMS) provides transportation order management and real-time access to order status so customers can track deliveries and on-time performances to communicate with other vested parties.

Plant Support

Plant support services that help processing and manufacturing plants transport their freight – whether raw materials, packaging, work-in-process destined for the processing plant, or finished products destined for distribution centers or end-users/buyers – are an essential link in the supply chain.

Asset-based providers with trailers, tractors, personnel, and the expertise needed to move materials in coordination with production schedules and execute shipping requirements allow manufacturers to focus on their production, not on material handling outside the plant.

Why Choose Colonial Cartage?

For over 70 years, Colonial Cartage has specialized in transporting temperature-controlled and ambient food-grade products. With a fleet of over 200 temperature-controlled trailers, warehousing facilities, and a state-of-the-art TMS, Colonial Cartage has the resources, experience, and personnel to provide customers with excellent transportation and warehousing services.

However, our assets and skills are not the only things that separate us from other logistics providers.

Our family-owned organization builds client relationships on trust, vision, and shared values. We don’t simply provide services; we create connections with our clients to become their long-term, dependable logistics partners.

Our business is built on providing customers with direct access to our decision-makers should they need rapid solutions to sudden problems, and our operational approach favors making the biggest impact with the least amount of noise so our clients can focus on their business first.

If you want to optimize your supply chain, enhance your customer’s experience, and reduce transport time and costs, contact us by phone or email. You can find our details on our Contact page or simply complete the short form you find there. At Colonial Cartage, we’re all about finding the best solution for you.