Less-than-truckload (LTL) shipping is an indispensable tool for businesses of any size, thanks primarily to its convenience and cost-efficiency. LTL solutions can utilize a pooled distribution model. Multiple shipments for the same destination are combined and routed through a hub or routed and sequenced by drop order on a single trailer. Instead of hiring an entire trailer, a shipper only needs to pay for the portion of the truck they use.

Full Truckload vs. Less-Than-Truckload Freight Services

LTL shipping refers to shipments that do not require an entire trailer and can be as little as 150 lbs. or up to 15,000 lbs. The shipment’s weight and dimensions (cube) will determine freight class, impacting rates. The higher the density, the lower the per hundredweight rate.

Full truckload (FTL) or truckload (TL) are at the opposite end of the spectrum. TL shipments range from 16+ pallets to a maximum of 44 to 48 pallets (depending on the height of the pallets and length of the trailer) or a total weight of 44,000 lbs.

The Cost of Less-Than-Truckload Freight Services

Many factors determine less-than-truckload pricing, the most important being:

- Location & distance: Most LTL carriers serve a specific region, usually around major metropolitan areas. If your freight needs to travel outside their coverage zone, it could be passed to another carrier at an increased cost.

- Dimensions & weight: Base LTL rates are calculated according to freight class (determined by the density of your cargo) along with its value, need for special handling, and how it fits in the trailer with other freight. Lower classes have higher density and less fragile cargo and, therefore, get charged less per weight and vice versa.

- Expedited or Guaranteed: By default, LTL shipments come with a delivery window that can be fluid and based on the carrier’s capacity and current lane volume. There are two additional services available at extra fees if you need to move your freight quickly: expedited shipment (which arrives faster than a standard shipment) or a guaranteed shipment (with a guaranteed delivery date and time). These rates can approximate the cost of a TL order.

- Special handling needs: LTL offers optional services not available from FTL carriers, such as liftgates for locations without a forklift and residential pickups or deliveries.

Industries That Rely On LTL Shipping

While many industries benefit from utilizing LTL as part of their supply chain system, there are a couple of specific markets that have been the main driving forces behind the explosive growth of LTL shipping in recent years:

eCommerce

LTL plays a significant role in moving freight securely and cost-effectively from suppliers to distribution hubs of major online retailers. Streamlined shipping processes automate most eCommerce tasks: from getting quotes, scheduling a pickup, and live tracking, all the way to automated delivery notification and online invoicing. LTL offers the flexibility, timeliness, and advanced technology required by eCommerce, plus it can also deliver heavy and bulky orders much more efficiently than small package carriers.

Food-grade products, consumer package goods (CPG), pharmaceuticals

The nature of fast-moving products with a high turnover rate, such as CPG, food-grade products, and medications, makes them an ideal match with LTL’s distribution reach and delivery capabilities. Partnering with an LTL carrier with scale, capacity, and a service area to handle time and temperature-sensitive cargo can enhance efficiencies further.

Freight Consolidation

As effective as LTL shipping is, there are additional ways to improve its model, especially in today’s competitive landscape, with rising costs and tighter delivery windows. One of the biggest challenges of LTL is that carriers must build enough volume in their trailers to make the loads profitable, leading to longer waiting times and delayed deliveries during low-volume periods or on less frequently used routes.

In most cases, the solution is freight consolidation through a 3PL provider. Freight consolidation alleviates these issues by combining multiple LTL shipments into a single full truckload or multiple-stop truckloads. The shipper of each LTL shipment benefits from lower costs by sharing an entire vehicle while reducing the risk of damaged products from less cargo handling. Most importantly, customers enjoy increased reliability and on-time deliveries.

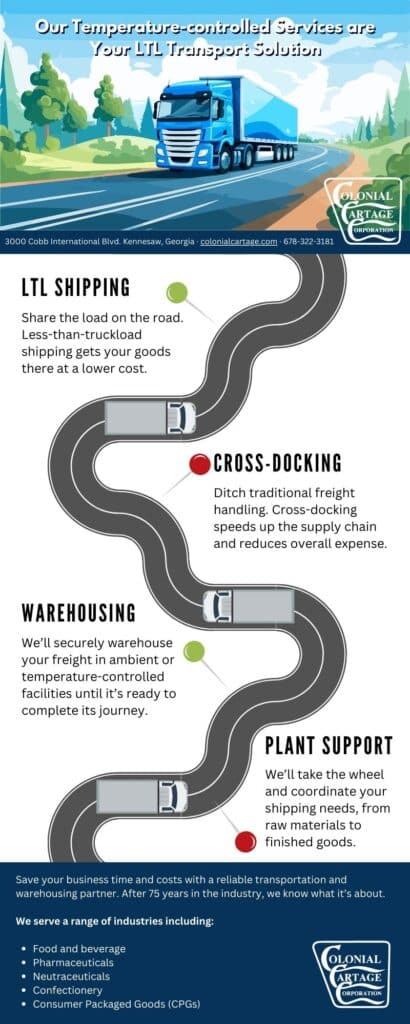

LTL Services Through Colonial Cartage

Colonial Cartage is a full-service, asset-based carrier providing one-stop food-grade dry and temperature-controlled LTL solutions and TL distribution services. Our service area covers 26 states. We have a fleet of over 260 temperature-controlled, food-grade trucks and trailers and 70+ years of providing dependable warehousing and transportation services to local and national enterprises. We have the experience, expertise, network, and scalable capacity to help you grow your business.

Contact Colonial Cartage today to learn more about our LTL services. Check our brochure.

FAQs

What are consumer packaged goods?

Consumer packaged goods (CPG) are fast-moving products used daily by average consumers that require routine replacement or replenishment. CPG examples include fresh produce, packaged food, beverages, cosmetics, toiletries, paper and storage supplies, and other consumables.

What is reefer shipping?

The use of temperature-controlled trailers to transport freight, including fresh and frozen foods, pharmaceuticals, cosmetics, and more, is referred to as reefer shipping.

What is the difference between LTL and TL?

Less-than-truckload (LTL) shipping is for shipments that do not require an entire trailer and a payload as small as 150 lbs. or up to 15,000 lbs. Truckload shipments are usually more than 16 pallets and up to a maximum of 44 to 48 pallets (depending on the height of the pallets and length of the trailer). Their total weight is 44,000 lbs.

What is freight consolidation?

Freight consolidation combines multiple LTL shipments into a single full truckload (FTL), which is more cost-efficient than pedal-run LTL deliveries, which have frequent delivery stops. Even with numerous stops, by combining several LTL shipments into a single full truckload going on the same route, the shipper of each LTL shipment benefits from lower cost, faster transit time, and reduced risk of damaged products.

What is cross-docking?

Cross-docking is the transfer of products from a truck or rail car to one or more outbound vehicles across a staging area within a short amount of time — eliminating the additional handling and storage required in a standard warehousing process. This strategy helps reduce costs and increase efficiencies.

What does a freight broker do?

A freight broker is an intermediary between a shipper and a transportation provider (over-the-road, rail, or ocean). According to the terms brokered, the broker arranges agreements and cost terms between the two parties to ensure the freight is picked up and delivered successfully.

What is a 3PL?

Third-party logistics (3PL) is the one-stop solution for outsourcing all or part of your warehousing, transportation, and fulfillment services to a professional supply chain provider.

What is breakbulk service?

Breakbulk service is a distribution model where outbound orders are picked directly from inbound cargo received in bulk at the loading dock. This service allows the shipper to bypass one aspect of the fulfillment process, making their inbound shipment to the breakbulk facility more cost-effective.

What is Colonial Cartage’s service area?

We operate in 26 states throughout the Southeast, Southwest, Midwest, Upper Midwest, and the Great Plains.

What kind of plant support do you offer?

We can assist with inbound transportation of raw materials to plants and outbound transportation of finished products from plants back to our other 3PL or private warehouses.

How extensive is your fleet?

We have more than 70 Peterbilt, Kenworth, and International power units, as well as more than 200 temperature-controlled trailers — all of which are company-owned, food-grade, and state-of-the-art safety equipment. In addition to our trucks and trailers, three mobile service vehicles can be dispatched both on-campus and throughout our service area.

Where is your headquarters?

Colonial Cartage headquarters’ is located at 3000 Cobb International Blvd in Kennesaw, Georgia.

How do you track shipments?

All of our trucks are tracked and logged with ELDs by KT and Brickhouse Security.